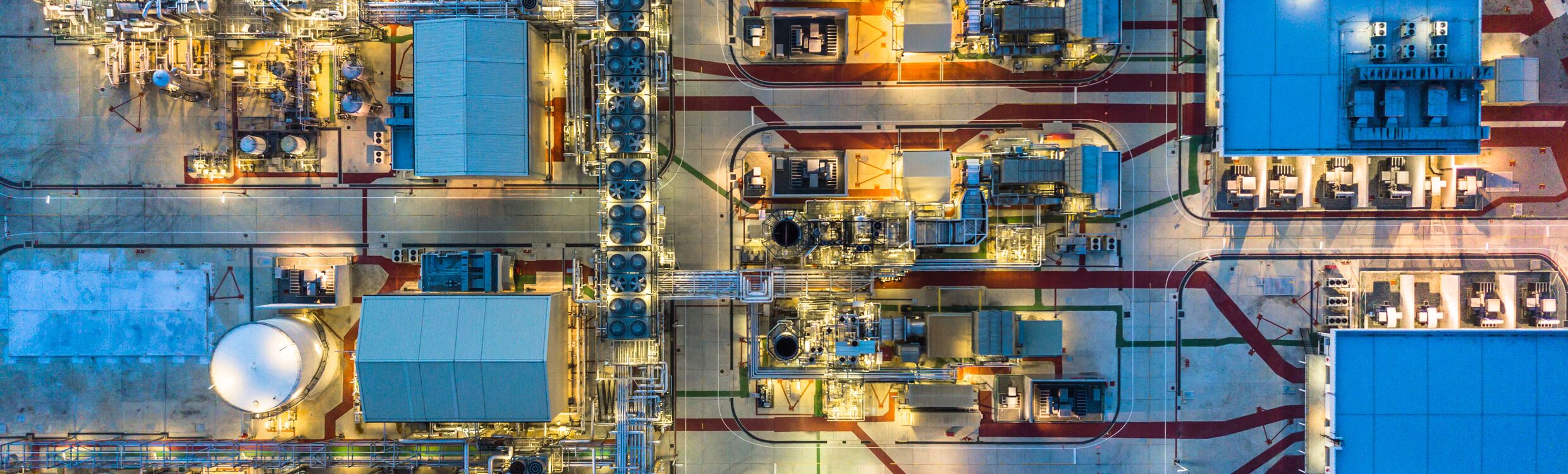

As international provide chains develop into extra interconnected and unstable, adopting digital options are now not a luxurious, they’re a necessity. This text examines how digitalization improves provide chain administration within the oil and gasoline business, highlighting a case research the place Fluor was in a position to successfully observe 2 MM supplies, forestall disruptions and enhance provide chain visibility.

Provide chain disruptions are one of many largest challenges dealing with the oil and gasoline business as we speak. From fluctuating demand to the influence of world occasions, the business should repeatedly adapt to keep away from expensive delays and disruptions. The complicated nature of oil and gasoline operations, the place supplies, tools and personnel are sometimes unfold throughout huge areas, provides to the problem. In response to those challenges, corporations are turning to digitalization to streamline their provide chains, achieve real-time insights and mitigate disruptions earlier than they develop into unmanageable.

Digitalization performs an important position in addressing provide chain restraints by automating processes, enhancing visibility and enhancing general operational effectivity. By leveraging digital instruments and platforms, oil and gasoline corporations can observe supplies and tools in real-time, cut back guide errors and scale based on their wants by responding swiftly to potential bottlenecks. As international provide chains develop into extra interconnected and unstable, adopting digital options are now not a luxurious, they’re a necessity.

An actual-world instance: Digitalization in motion. A strong instance of how digitalization can remodel provide chain administration is seen within the partnership between Fluor and Hexagon’s Jovix® system. In a hit story involving a big grassroots oil refinery challenge in Kazakhstan, Fluor and Hexagon partnered to enhance the refinery’s supplies administration processes. The challenge—referred to as the Future Progress and Wellhead Stress Administration Mission (FGP-WPMP)—aimed to extend crude oil manufacturing on the Tengiz Oil Subject by 260,000 bpd, with an general funding of $36.8 B.

Managing a challenge of this scale required a strong and extremely environment friendly supplies administration system. Fluor determined to implement Jovix, an award-winning Materials Readiness® utility designed particularly for industrial building and materials fabrication. By integrating Jovix into its operations technique, Fluor was in a position to improve visibility into the provision chain utilizing radio frequency identification (RFID) tags, barcodes and rugged tablets.

The challenge initially deployed 500,000 RFID tags to trace supplies, a quantity that ultimately grew to embody the monitoring of two MM supplies over the course of the challenge. By automating materials identification and monitoring, Jovix considerably improved the circulate of supplies throughout numerous international areas, together with upstream fabrication outlets and modularization yards in South Korea.

The digitalization of provide chain processes not solely streamlined operations but additionally helped Fluor keep away from potential provide chain bottlenecks. This was particularly essential in a challenge of this dimension and complexity, the place delays may have had a major monetary and operational influence. With new, automated monitoring options, together with gate readers and vehicle-mounted readers, materials location updates had been out there in actual time, enabling managers to make knowledgeable choices rapidly.

The position of digitalization in stopping provide chain disruptions. One of many key advantages of digitalizing provide chain administration is the power to mitigate disruptions earlier than they escalate. In Fluor’s case, integrating RFID tags and barcoding know-how allowed for seamless monitoring of supplies from fabrication websites to the sector. This degree of visibility meant that Fluor may anticipate potential delays, regulate schedules and reallocate sources as obligatory, making certain the challenge stayed on observe.

By digitizing provide chain operations, oil and gasoline corporations can obtain larger transparency throughout the whole worth chain. They will monitor the circulate of products, tools and personnel in actual time, which helps cut back inefficiencies, reduce downtime and optimize using sources. That is notably essential within the oil and gasoline business, the place delays or lacking supplies could cause substantial monetary losses and operational challenges.

Along with mitigating disruptions, digitalization additionally improves collaboration throughout groups and suppliers. Via built-in digital platforms, all stakeholders can entry up-to-date info on stock ranges, cargo statuses and manufacturing schedules, fostering higher communication and coordination. That is essential in complicated tasks just like the Tengiz enlargement, the place supplies and tools had been sourced from a number of suppliers throughout the globe.

Trying forward: The way forward for digitalized provide chains. Because the oil and gasoline business continues to face new challenges, the significance of resilient and agile provide chains can’t be overstated. Digitalization is about to play an much more vital position in shaping the way forward for provide chain administration. Superior applied sciences like synthetic intelligence (AI), machine studying and predictive analytics are anticipated to additional improve the power to anticipate provide chain dangers and optimize decision-making processes.

The success of Fluor’s deployment of Hexagon’s Jovix resolution highlights how digital instruments will be leveraged to rework provide chain operations within the oil and gasoline sector. By rising visibility, enhancing materials monitoring and automating guide processes, Hexagon helped be sure that the Tengiz Enlargement Mission was executed effectively and on time. The challenge’s means to trace 2 MM supplies and combine RFID know-how throughout international provide chains is a testomony to the facility of digitalization.

For oil and gasoline corporations seeking to keep away from the type of enterprise disruptions brought on by provide chain restraints, the answer lies in adopting digital platforms that present real-time information, automate workflows and improve collaboration. As demonstrated within the Kazakhstan challenge, digitalization is not only about streamlining processes, it’s about constructing extra resilient, adaptive provide chains that may stand up to the uncertainties of as we speak’s international economic system.

About Hexagon

Hexagon is a world chief in digital actuality options, combining sensor, software program and autonomous applied sciences.

Hexagon’s Asset Lifecycle Intelligence division helps purchasers design, assemble and function extra worthwhile, secure and sustainable industrial amenities. We empower prospects to unlock information, speed up industrial challenge modernization and digital maturity, enhance productiveness and transfer the sustainability needle.

Our applied sciences assist produce actionable insights that allow higher decision-making and intelligence throughout the asset lifecycle of business tasks, resulting in enhancements in security, high quality, effectivity and productiveness, which contribute to financial and environmental sustainability. Hexagon (Nasdaq Stockholm: HEXA B) has roughly 22,000 staff in 50 nations and web gross sales of roughly €4.3 B. Be taught extra at hexagon.com, and observe us @HexagonAB