A analysis crew has achieved progress in learning van der Waals (vdW) contacts for two-dimensional (2D) electrical gadgets. The crew developed an modern all-stacking approach for fabricating 2D electrical gadgets, optimizing the interface contact between 2D supplies and metallic electrodes. The examine was printed in Nature Communications.

In typical fabrication processes for 2D electrical gadgets, the deposition of metallic electrodes is a vital step. Excessive-energy metallic atoms deposited on the floor of 2D supplies can simply injury their lattices, finally degrading the machine’s electrical efficiency. Due to this fact, reaching dependable electrical contact between 2D supplies and metallic electrodes is essential for bettering the efficiency of 2D electrical gadgets.

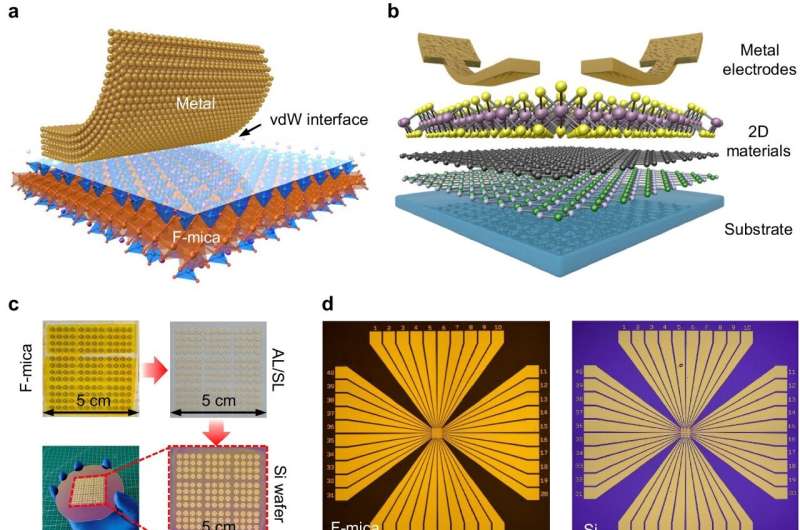

Latest analysis has proven that for 2D digital gadgets, realizing the vdW contact holds promise for fixing the above issues. The vdW contact refers back to the interplay between 2D supplies and metallic electrodes via vdW forces. This technique avoids introducing quite a few defects and may obtain good electrical contact, providing higher operability and potential for large-scale utility.

To realize dependable 2D vdW contacts, the crew developed an all-stacking approach. This system allowed for the direct stacking of metallic electrodes onto 2D supplies throughout the fabrication of 2D electrical gadgets, avoiding steps like metallic deposition and thus defending the 2D supplies from injury whereas reaching glorious electrical efficiency.

Particularly, 2D electrical gadgets fabricated utilizing this method had sharp metal-semiconductor contact interfaces, with easy and clear vdW gaps on the interface and no metallic atom doping on the 2D materials aspect. This indicated that high-quality vdW contact had been fashioned between the metallic electrodes and the 2D semiconductor.

As a result of improved contact interface, 2D semiconductor transistors fabricated utilizing this method exhibited greater than 95% discount in off-state present and a 50% lower in subthreshold swing in comparison with these fabricated utilizing metallic deposition processes. In addition they possessed the next on-off ratio, making them extra advantageous for low-power built-in circuits.

To display the potential of the all-stacking approach for wafer-scale manufacturing, the crew fabricated an array of field-effect transistors based mostly on monolayer molybdenum disulfide utilizing this method. The machine yield was as excessive as 98.4%, exhibiting glorious consistency and stability.

The common on-off ratio of the transistor array was 6.8×106, with 91.3% of the gadgets having an on-off ratio better than 106. The wonderful efficiency and excessive consistency of the transistor array demonstrated the benefits of the all-stacking approach in reaching dependable contact for 2D digital gadgets.

The all-stacking approach developed on this examine optimizes the interfacial contact between 2D supplies and metallic electrodes, offering an environment friendly, high-quality, and common strategy for the preparation of 2D digital gadgets. The examine is predicted to offer a brand new technical path for the industrial-level manufacturing of future 2D digital gadgets.

The analysis crew was led by Prof. Zeng Hualing, Prof. Qiao Zhenhua, and Prof. Shao Xiang from the College of Science and Expertise of China (USTC) of the Chinese language Academy of Sciences (CAS).

Extra data:

Xiaodong Zhang et al, Dependable wafer-scale integration of two-dimensional supplies and metallic electrodes with van der Waals contacts, Nature Communications (2024). DOI: 10.1038/s41467-024-49058-7

Quotation:

Engineers combine wafer-scale 2D supplies and metallic electrodes with van der Waals contacts (2024, June 19)

retrieved 20 June 2024

from https://techxplore.com/information/2024-06-wafer-scale-Second-materials-metal.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.