Advances in 3D printing have enabled many purposes throughout a wide range of disciplines, together with drugs, manufacturing, and power. A variety of various supplies can be utilized to print each easy foundations and superb particulars, permitting for the creation of constructions with tailor-made geometries.

Nonetheless, creating constructions with micro-scale, exact inner voids and channels nonetheless poses challenges. Scaffolds utilized in tissue engineering, for instance, should comprise a three-dimensional complicated community of conduits that mimic the human vasculature. With conventional additive manufacturing, the place the fabric is deposited layer by layer, it is troublesome to print such intricate inner options with out sacrificing time, accuracy, and assets.

To deal with this difficulty, Philip LeDuc and Burak Ozdoganlar, professors in mechanical engineering at Carnegie Mellon College, are spearheading the event of the freeform 3D ice printing (3D-ICE) course of. This system makes use of a drop-on-demand 3D printing method with water as an alternative to standard printing inks. A piezoelectric inkjet nozzle ejects tiny water droplets onto a construct platform maintained beneath the freezing level. This causes the droplets to freeze shortly after contact.

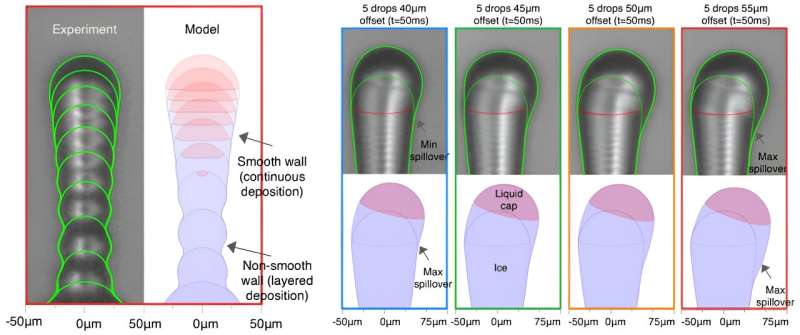

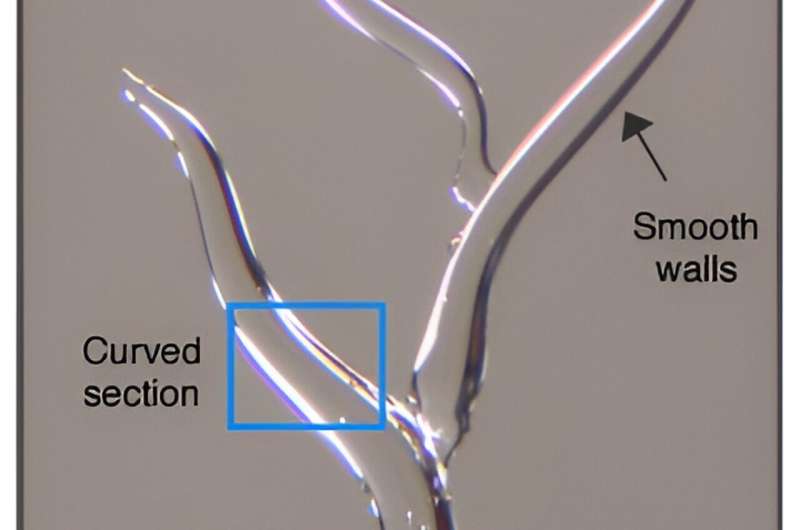

Uniquely, the method will be managed to deposit a number of droplets earlier than the earlier droplet is frozen. As such, a water cap stays atop the printed construction, and the freezing progresses from the underside. This permits the creation of constructions with clean partitions, transitions, and branches. Options as small as human hair will be fabricated.

As extra droplets are deposited, an ice construction takes form on the construct platform. The diameter, peak, and relative smoothness of the pillar’s geometry will be adjusted by controlling the speed of droplet deposition, and the temperatures of the printing floor, droplet, and workspace.

If the construct platform is shifted such that the incoming droplet hits at an angle, the freeze entrance will rotate accordingly, making it doable to supply branching, curved, and overhanging constructions that may be difficult or unattainable to print with different 3D printing methods with out further help supplies.

“3D ice may very well be used as a sacrificial materials, which implies we may use it to create precisely-shaped channels inside fabricated components,” stated LeDuc. “That might be helpful in loads of areas, from creating new tissues to delicate robotics.”

For the reason that outset of their mission, LeDuc and Ozdoganlar’s analysis workforce has investigated methods to make sure that the 3D ice course of is predictable and reproducible. Of their latest article printed within the PNAS. they describe 2D and 3D numerical fashions to elucidate the physics behind 3D ice, together with warmth switch, fluid dynamics, and the speedy section change from liquid to stable through the printing course of.

Their 2D fashions map the development of straight pillars, together with the respective results of layered and clean deposition. “The frequency of droplet deposition impacts the peak and width of the construction,” stated Ozdoganlar. “For those who deposit shortly, the water cap grows, producing wider constructions. For those who deposit slowly, then the construction turns into narrower and taller. There are additionally results from the substrate temperature. For a similar droplet deposition charge, a decrease substrate temperature produces taller constructions.”

Their 3D fashions map the development of indirect constructions by predicting the rotation of the freeze entrance. “You have got all forms of warmth switch, together with conduction to the underside and convection to the encompassing space,” stated Ozdoganlar. “All these issues are working concurrently once you deposit every droplet. For those who deposit obliquely, a part of the droplet spills over on the aspect of the pillar earlier than it freezes. And as you retain depositing at that angle, the freeze entrance slowly modifications form, and the construction grows in that course.”

Along with additional refining their mathematical fashions, LeDuc and Ozdoganlar’s labs at the moment are trying to scale up 3D-ICE and discover its efficacy throughout a variety of purposes. As an illustration, present methods in tissue engineering typically contain designing generalized tissues.

3D-ICE may quickly make it doable to print customized tissues that match the distinctive construction of every affected person’s vasculature, assembly the precise wants of the affected person’s physique. Furthermore, 3D-ICE will allow the creation of purposeful tissue constructs to be used in understanding completely different ailments or growing new therapeutics.

“Once I first began my lab, I might by no means have imagined that we’d be 3D printing ice, and utilizing it to create tissues to assist folks,” stated LeDuc.

“However our analysis has developed. It has introduced folks like Burak and myself collectively, and everybody brings all kinds of various views and capabilities to the desk. It is a great factor to do that work collectively the place the sum of the components is certainly larger than the person components on this transdisciplinary science and engineering.”

Extra info:

Ozdoganlar, O. Burak et al, Physics of microscale freeform 3D printing of ice, Proceedings of the Nationwide Academy of Sciences (2024). doi.org/10.1073/pnas.2322330121

Quotation:

Understanding the 3D ice-printing course of to create micro-scale constructions (2024, July 15)

retrieved 21 July 2024

from https://techxplore.com/information/2024-07-3d-ice-micro-scale.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for info functions solely.